Armstrong's 51-C2 and the Millville/Muncie Connection

by Richard Wentzel

Reprinted from "Crown Jewels of the Wire", January 1991, page 22

The recent discovery of the new CD 228.5 Armstrong 51-C2 prompted the

research which led to this tale of competitive cooperation. But first, some

background information is in order.

Early in 1989, I was approached by John and

Carol McDougald relative to providing information on insulator production in Millville

for their new two-volume reference library. During the course of our initial

correspondence on that matter, I was made aware of the existence of the 51-C2.

This immediately sent me on a search through the Armstrong archives for anything

pertaining to this previously unknown insulator.

Unfortunately, the plant's

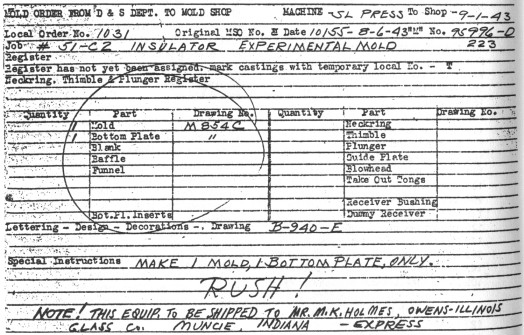

drawing file yielded nothing, likewise the correspondence file. I continued my

search with increasing discouragement until, in the mold order file, I chanced

upon a folder labeled "51-C2 INS." Opening the folder, I found a

single piece of paper as the legacy of Armstrong's 51-C2. (see below)

What I had uncovered was a mold shop order, dated September 1, 1943 --

complete with explicit instructions to send the finished mold assembly to

Armstrong's main competitor. Faced with such an unexpected scenario, I hoped to

find a reasonable explanation for an Armstrong/Owens-Illinois collaboration.

Additional information on the "discovery" of the 51-C2 was

forthcoming at the Allentown National in 1989. The piece had surfaced in a

Kansas collection, indications being that it was dug in the Midwest. This

information seemed to fit the puzzle as it related to the whereabouts of the

mold that produced the insulator.

Remaining to be discovered, however, was the

underlying factor which led these two manufacturers to combine efforts, and

produce what could essentially be considered a hybrid insulator -- an item

apparently formed of Owens-Illinois glass in an Armstrong mold.

The answer

finally surfaced in an unlikely corner of the Whitall Tatum / Armstrong archives.

Dusting off a thick black binder grandiosely entitled, ASTM Committee D-9

Sub-Committee-V Section-C Glass Insulators, I soon found the reasonable

explanation for which I had been searching.

It seems that Victor F. Hammel, of

Whitall Tatum, later Armstrong, and Minot K. Holmes (referred to on the mold

shop order), manager, Owens-Illinois Insulator Division had both served on the

same subcommittee of the American Society for Testing Materials (ASTM) beginning

May 20, 1937. Their relationship developed over the next three and a half years

as the group attempted to formulate various standards for testing glass

insulators. Hammel assumed chairmanship of the subcommittee in June 1938.

Sandwiched between official subcommittee documents, personal correspondence

between Hammel and Holmes indicate an unusual degree of association between their respective employers, stemming virtually from the initial

introduction of the two men. In the late spring and early summer of 1937,

Whitall Tatum was in the midst of developing its CD 240.2 1025 power insulator.

Company purchasing agents were experiencing some difficulty locating a supplier

for threaded brass bushings to be inserted in the 1025. Manufacturers contacted

by Whitall Tatum were unanimous in their unwillingness to tool up for such a

small (1000 to 2000 bushings) production run at a cost economically feasible to

the 1025 project.

Mentioning his predicament to Holmes, Hammel received a

response dated April 29, 1937 indicating his competitor's willingness to supply

the needed item in any quantity desired. Four days later, Whitall Tatum placed

an order for two thousand bushings.

The paper trail documenting the committee

alliance of these two men ends in December, 1940. Obviously, the relationship

formed during that time continued at least another three years until the 51-C2

venture. From the documentation available, it is difficult to determine the

length of time Holmes and Hammel remained in close association with each other;

and to what extent their efforts further affected the product lines of either

company.

Regardless, the level of cooperation demonstrated by the two major

insulator manufacturers of the period provides an interesting counterpoint to

today's corporate/industrial operational ethics.

As an aside, the following

information is presented in the context of the preceding story:

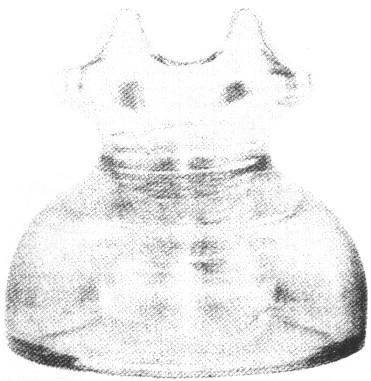

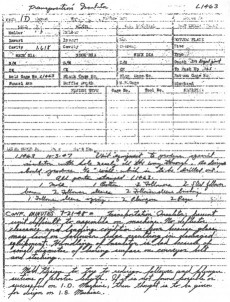

The above photograph pictures two CD 1049 mid-span transposition insulators.

The insulator on the left was retrieved from Armstrong's insulator sample

shelf. The hole does not go all the way through, and the insulator has no

embossing. It fits the physical description of Figs. A & B, Register #L1463

-- "A.C.Co." Transposition Insulator.

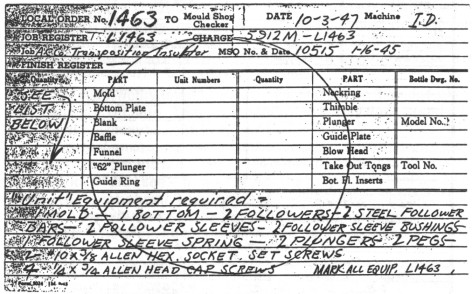

Figure A. Job Order for L1463 A.C.Co. Transposition Insulator.

The insulator on the right is the more familiar version, exhibiting a shorter

skirt, and bears the Owens-Illinois trademark embossed between small numbers

indicating mold number and year of manufacturer.

No physical evidence exists to

prove or disprove a possible collaboration between the two companies on this

item. Bear in mind, however, that many manufacturers produced insulators of

similar design, generally in response to the intended user's design

specifications.

Medium Image (132 Kb)

Large Image (289 Kb)

|